This is Home. We treat it right.

Upper Thompson Sanitation District has been providing high quality, cost-effective water reclamation services to the Estes Valley for over fifty years. To continue to provide this public service, meet future water quality standards and continue as responsible stewards of our environment, we must address our outdated and ailing infrastructure.

The Challenge

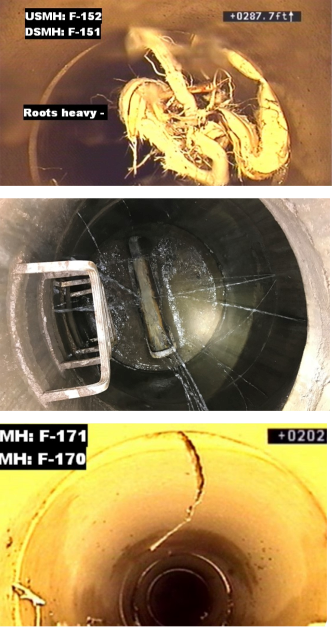

Our District faces the challenge of an aging treatment facility that has not been significantly updated in over 50 years and is nearing the end of its useful life. Our wastewater treatment infrastructure is costly to maintain, has limited capacity and is not equipped to achieve the higher water quality standards that will be mandated in the next few years by the Environmental Protection Agency (EPA) and Colorado Department of Public Health and Environment. Additionally, due to their age, the existing facilities do not meet current building code and safety requirements.

The Solution

To meet these challenges, we are building a new water reclamation facility (WRF) and lift stations. The new WRF will be located on a 9-acre site near our current facility east of Estes Park. When completed, the new WRF will ensure compliance with future water quality standards and protect the Big Thompson River. This new facility will incorporate state-of-the-art treatment technologies that will allow us to serve the community’s needs for decades to come. These proactive solutions today are necessary to prevent more costly problems tomorrow.

Cost of the Project

We are still determining the total cost of the new water reclamation facilities. Similar to many public infrastructure projects, our project is impacted by supply chain issues, workforce shortages and high material costs. Right now, we are in the process of value-engineering this project as well as pursuing grants and low-interest loans. This approach will ensure we are building an advanced, environmentally friendly facility that will serve the Estes Valley for generations at the lowest possible cost and with the least burden on our ratepayers.

Funding the Water Reclamation Facility

This project is expected to be financed using District capital reserves, customer service fees, and long-term, low-interest loans from the Colorado Water Resources and Power Development Authority’s State Revolving Fund, the EPA’s Water Infrastructure Finance and Innovation Act and/or the United States Department of Agriculture. The District is also actively pursuing state and federal grant opportunities for design and construction.

Service Fees

Service fees are subject to the Board of Directors’ annual evaluation based on operating costs, total project cost, grants obtained, and loan interest rates at the time of the WRF’s completion.